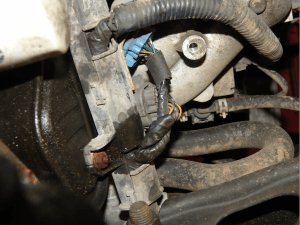

2002 Chevrolet Astro Van was referred to me by two different shops because the battery would go dead quickly and at one of the shops the battery got very hot and the sub harness from the brake proportioning valve switch caught on fire. The battery had been replaced, the master cylinder was replaced and unfortunately the the harness was thrown away. After talking with the customer and both shops in detail and when, it was mention to me about how hot the battery had gotten, I decided to trace the battery cable and look for a major short. It did not take too long to find this one. The next picture shows the short as I found it. It was located at the passenger side of the engine behind the steering linkage.

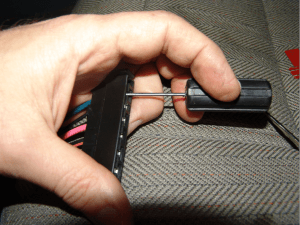

I pulled the cable out for a better view.

I decided that the cable only had a superficial wound and that it really only needed to be sealed. I rubbed some silicone sealer onto the wound and let it cure out.

The next morning I wrapped it with electrical tape to further seal it.

Tucked it back into the loom.

I rotated the loom so the the split seam was not facing down on the crossmember.

And secured the assembly in place with a couple of wire ties.

Apparently the harness had never been secured to the crossmember and I could not even find a location hole where it should have been fastened. With the cable having been free to move around it had gotten very close to the steering linkage and in particular on a hard left turn the linkage would rub into the cable. I asked the customer if he had ever noticed anything strange while turning and he said some times it would stall and the voltmeter would jump around. Well I guess so!!