Being in the automotive business I generally keep up with with headlines in the automotive field. I was recently watching the news one morning, and there was a piece on a recall by Toyota on several of it’s late model vehicles for problems related to the accelerator pedals getting stuck on the floor mats. Seems like a pretty simple fix for a fairly serious problem. Remove the floor mat until a proper part can be designed and installed in all of the recalled vehicles.

I did not think too much about this problem until, on an updated report I saw where fatalities were involved. I figured the gas pedal stuck on one of these vehicles and a pedestrian was hit and killed. To my surprise I read that a family of four had died when their 2009 Lexus ES350 accelerated to more than 120 mph when the driver lost control of the vehicle, hit a SUV, bounced off an embankment, flipped over several times, caught on fire and killed everyone in the vehicle. Absolutely terrible!!!!

Other than the obvious tragedy of the loss of life. There are several things that really bother me about such a needless accident.

Number one is that there was enough time for some one in the car to have called 911 for help in the matter, and apparently no help was received in time. I do not know the exact timelines, but I think it would take at least 30-60 seconds from the time the decision to call was made until the accident happened. It would have probably taken another 30 seconds or possibly much longer to actually decide to call 911.

Number two is that the driver was a California Highway Patrol Officer. A position that one would think has required training in automotive safety as that is part of the job description.

Number three the driver nor anyone in the car thought to turn the ignition off, or shift the transmission into neutral. Either one of which would have prevented either the scale of the accident or the fact that there was even an accident at all!!!!!!

If the vehicle had a keyless ignition, the ignition button would have had to be pushed and held in for three seconds before the engine would die (a fail safe to prevent accidental turn off of the engine while the vehicle is moving).

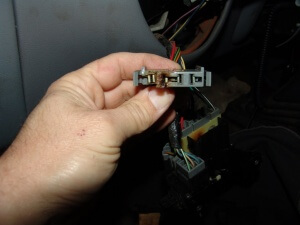

The shifter does require two movements to change from drive to neutral. Over and up.

An interesting point released by the NHTSA is that 150 pounds of pedal force is needed to stop one of these runaway vehicles as opposed to the normal 30 pounds of pedal force. Can you apply 150 pound of force to the brake pedal? Better have a plan “B”.

This information makes reading your owners manual and being familiar with your vehicle seem kind of important doesn’t it?

I know that I may take information like this for granted, because I grew up hearing stories from my father who was a mechanic at a GM dealership in the early to mid sixties when the “new cruise control system” was causing similar problems. It would sometimes engage and floorboard the accelerator pedal. I remember him saying that he was test driving one of these cars and it floor boarded on him “I tried to turn the cruise off but it would not disengage so I reached over and turned the ignition off”. Being a mechanic myself I have had similar problems over the years. Two cruise control systems floor boarded, and one accelerator return spring broke after a hard acceleration. Turning the key off worked every time.

The thing that is even more shocking to me, is that I have heard no one in the media talking about the lack of what should be common sense on the part of vehicle operators.

ANY VEHICLE is capable of a floor boarding situation. Whether it is a mechanical issue as simple as a floor mat keeping the gas pedal pushed down or an electronic problem, the situation can be overcome by turning the ignition off or putting the transmission in neutral.

Two simple little acts that would have saved the lives of at least four people and probably more. Everyone should know how to efficiently do both in any vehicle that they get into.

Maybe something else people should realize is that a vehicle is no different than a gun, in that if not handled properly it will kill you!!!!

Yes, Toyota is responsible for creating a dangerous situation to start with, but do we as a people have to slip into such a state of ignorance that we cannot THINK enough to save our own lives.

I know that I am not the norm, but I do not get behind the wheel of anything without having an exit strategy and constantly updating my plan as I drive. I was taught this as a child, and it is just second nature now.