The other epiphany that I had while thoroughly investigating this process was that I could get to the one hidden screw if the passenger side of the floor duct was gone. Then I thought how could it best be removed without disturbing anything else? I could cut it off with a saw but then what? Figure out a way to patch it back together?

Wait a minute… doesn’t the Ford Motor Company sell parts? I called the local Ford dealership and found that the part lists for about $22 USD and that one could be obtained within two days. I called my customer and informed him of what I had found and offered him these two scenarios:

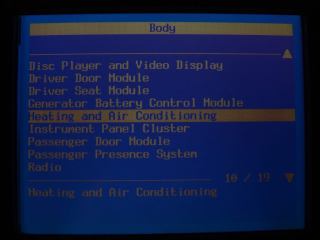

1. The vehicle would be ready to pick up the next day and the bill would reflect parts plus 7 hours labor. The job would involve removing the front seats, center console, steering column and dash assembly. Evacuate and recover the fluids. Move a few things out of the way (carpet, brackets and etc.) and finally remove the HVAC case assembly. Then the floor duct could be removed and the actuator replaced.

2. The other option would be to wait one extra day, remove the seats, center console and move a few things out of the way (carpet, brackets and etc.). Cut the old floor duct in half. Replace the actuator and install a brand new floor duct minus the one rear screw. I informed him the bill would reflect 3.5 hours labor plus parts. The replacement floor duct lists for about $22 USD.

He asked what would be the detriment of leaving the one screw out? I told him that the corner of the floor duct where the screw was could potentially sag and let a slight amount of air bleed out of the gap instead of being sent to the front and rear floor boards when the system was set to heat. Also that the a noise issue could arise.

His next question was : “Steve, given your years of experience, what would you do if this was your own personal truck?” Being a brutally honest person I told him: “From what I have researched and visually inspected for myself that screw would never be put back in my truck regardless of how I replaced the actuator. That coupled with what I suspected about how the floor duct could be removed, would force me to remove the floor duct in pieces, replace the faulty actuator and install a new floor duct minus that one screw.”

I stated “suspected” because I only had anecdotal information that the floor duct could be removed and installed with no problem. If only that one screw was missing.

I further stated that with his blessing I would like to cut the floor duct and remove it in pieces. Then repair the damaged floor duct and put it back into one rigid piece. This would allow me to test the installation theory. If it worked we would continue with the second option plan. If it did not work I would furnish the new floor duct at my expense and revert back to the option one plan. I also stated that I would also be testing for potential air leaks, noises and vibrations during reassembly. If any were encountered we would also revert back to the option one plan. The only gamble on his part would be the one extra day without the vehicle and possibly saving 3.5 hours of labor costs.

He agreed and I proceeded to cut the floor duct. Cutting the duct was slightly more awkward than I had anticipated because I wound up having to use a hacksaw blade without a handle to cut the duct from the under side. I also had to lift the bottom of the duct off of the floorboard where it rests. I did all of this because I did not want to accidentally cut into the floorboard. Other than that it worked quite well. Access to that one screw was then easy.

I taped the floor duct back together using “Gorilla Tape” to make sure a new floor duct could indeed be re-installed back into the dash and I found that it could be done. I had planned to also use plastic welder to reinforce the repair but the tape made it so rigid that I did not feel the need to. A new duct was ordered and the customer was updated on the repair.

As stated very early on if the floor duct was out of the way the actuator would be almost easy to replace. There are two screws that hold it in place. A ratchet and short 8 mm socket are needed or an 8 mm wrench.

The actuator’s wiring harness connector is at the firewall side of the actuator.

The replacement actuator is Motorcraft part number YH-1933, Ford Motor company part number DL3Z-19E616-A.

The original had a white shaft and the replacement was black. That could have been done because the plastic material was changed or just so it could be easily identified, maybe both. Other considerations that I had while doing this repair was the low cost of the part, the fact that it had already failed after just four years in service and the “Made In China” label. It is very likely that this actuator will fail and need to be replaced several more times in the lifetime of this vehicle. Could you imagine the unneeded stresses and subsequent related parts failures if the complete assembly was removed two to four times over the next 8 to 16 years? I could and that is why I ultimately decided to do it the way that I did.

I encountered a minor problem when installing the new floor duct. There is an extra/added piece of plastic webbing at the rear of the “pocket” where the actuator is located. This was preventing the new floor duct from going past the actuator.

I used a pair of duck bill pliers to remove the bulk of the plastic and then went back and cleaned up the edges with a knife and then a Dremel tool. I would assume the addition of this webbing has been some sort of running production change. In doing this style of repair on a later model truck one might encounter that same webbing and it could make it more difficult to remove the original floor duct. I compared to two parts extensively and the only reason that I could come up with for the additional webbing was obsessive designing or possibly to prevent the actuator harness from being disconnected/damaged by accident or on purpose before the main HVAC assembly is installed in the vehicle.

The new floor duct has to be installed at a slight angle and then rolled into position.

There is also this white aspirator tube that has to be dealt with during removal and installation of the floor duct.

After the new floor duct was installed and the truck was going back together. I temporarily installed the center console and tested the system out. This was without installing the other brackets, trim panels or fully putting the carpet back into place. The system is partially inoperative with the rear controls disconnected. I directed the air flow to the floor vents and checked for noises (whistles, hisses or vibrations) at various blower speeds and temperature settings and none were present. I also placed my fingers between the driver’s and passenger side of the floor duct and the firewall padding to feel for any air movement. Granted I could not reach the suspect corner but no air movement was felt and yes I took my gloves off to do that.

Since I could not fully reach the corner where the missing screw would have been I decided to introduce a foreign object behind it that would make an audible difference in the tone of the air flow if it moved past an air leak. I used a folded piece of paper and a piece of light cardboard and no leak could be detected. My last choice of material turned out to be a common sponge in a plastic wrapper. I slid it in from the driver’s side and pushed it across to the passenger side going right past the missing screw location. I did this several times and there were absolutely no audible changes. I did notice a very slight movement in the floor duct when the sponge was inserted and moved from one side to the other. I did not know for sure if it was lifting a low corner or just flexing the plastic in general. I strongly suspected that there was just general deflection since the angles at the junction point to the main HVAC case and the thickness of the material make that area quite rigid.

The customer shows up as I am finishing the truck and picking up my tools. I was joking with him about finding missing objects under the seats and center console including his eyeglasses and lipstick. Not his color he says so we suspect it was his wife’s. He asked where in the world I found the sponge that was also laying on the seat? I explained to him how I had used it to test for air leaks and he thought that was very interesting. We then talked about just leaving it in there just in case the plastic wanted to shift and a noise might develop. He asked if the sponge would fall out and I explained that due to the compression of the sponge and the resultant spring action, that the sponge would stay in place. I put it back in at his request and feel absolutely no remorse and not one bit “hacky” for doing so!!!

More about my last comment in the follow up to this repair.

Part 1 of 4.

Part 2 of 4.